CNC Controlled Automatic Coil WinderAN240 / 480 / 720 Series

AN240 / 480 / 720 series are excellent winding machines in versatility that can be widely used for variously-shaped bobbin winding types such as relays, solenoids, ignition coils, and others.

Regarding one of the challenges of winding systems, "multi-objective production", Nittoku's tool transfer system solved the problem to vastly reduce down-time for specification changeovers. Also its modular system permits addition/removal of processing modules for soldering, taping or assembling to/from system line, the system can be built up as best suited manufacturing line to meet the market needs.

Further, various options will substantially increase manufacturing efficiency: double traverse mechanism for finer winding, direct spindle mechanism for faster winding and decreased running costs, dedicated software for perfect layer coil winding, etc.

|

|

|

| AN480 |

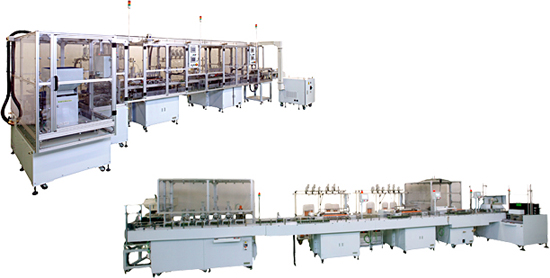

AN720-24-50DS

with conveyor |

AN720-18-50DS

Bobbin transfer type |

AN240 / AN480

| Model |

AN240-(Spindles)-(Controller) |

AN480-(Spindles)-(Controller) |

| No. of spindles |

3 / 4 / 6 / 8 / 12 |

6 / 8 / 12 / 16 / 24 |

| Spindle turn speed * |

Standard spec. : Max. 10,000 rpm

Hi speed spec. : Max. 16,000 rpm

Special spec. : Max. 20,000 rpm |

| Controller |

Model : NSC50

Programmed by PC (sequence / winding program) |

| Controllable axes |

4 |

| Power supply |

AC200V±10% 3-phase 50/60 Hz |

| Power consumption |

Approx. 2.5 kVA |

Approx. 3.0 kVA |

| Air supply |

Min. 0.5 MPa |

| Air consumption |

Approx. 60 l/min. (including conveyor) |

| Machine dimensions |

800(W)x720(D)x1,030(H) mm |

1,060(W)x720(D)x1,030(H) mm |

| Machine weight |

Approx. 370 kg |

Approx. 450 kg |

* Spindle rotation speed changes by coil specification.

Spindle direct drive type winding machine

| Model |

AN720-18-50DS |

AN720-24-50DS |

| No. of spindles |

Max. 18 |

Max. 24 |

| Spindle rotation speed * |

Max.24,000 rpm |

| Controller |

Model : NSC50

Programmed by PC (sequence / winding program) |

| Controllable axes |

24 |

32 |

| Power supply |

AC200V±10% 3-phase 50/60 Hz |

| Power consumption |

Approx. 2.0 kVA |

Approx. 2.2 kVA |

| Air supply |

Min. 0.5 MPa |

| Air consumption |

Approx. 50 l/min. (excluding vacuum air) |

| Machine dimensions |

1,080(W)x1,360(D)x1,460(H) mm |

| Machine weight |

Approx. 1,150 kg |

* Spindle rotation speed changes by coil specification.

Spindle Direct Drive System

- Timing belt and/or pulley is not required

- No need to worry about jolting out of alignment in speeding up

- Quiet operation

- Easy maintenance

- Specific control on each spindle

- Dust-free from the belt

- Rear cover (safety measure) of the belt is not required

Free System Configuration

- You can choose transfer method (tool free flow, bobbin transfer, table transfer, etc.) according to various types: mass/multi-production, small/multi-production, with or without specification changeovers, or post processes.

- Block system of specific NC Control allows operation by unit or segmentation operation for the system.

- Even the bobbin which is difficult to transfer may be automated in post process with various transfer tools.